Adam Whitney is a Metalsmith who currently resides in his home state of Vermont. He has worked & lived throughout the United States and abroad obtaining experience from a range of projects and teaching. At his studio he spends his time hammering sheet metal into volumetric forms, constantly exploring the possibilities of silversmithing and pushing his understanding and knowledge of the craft. When not in his studio Adam travels to work on projects and to teach workshops, taking his passion for Metalsmithing to wherever he goes.

Adam received his BFA in Crafts / Materials Studies from Virginia Commonwealth University where he concentrated in Metalsmithing. He has worked as a bench jeweler at Dransfield Jewelers, Metals Studio Coordinator at Penland School of Crafts, taught Jewelry Design at Raffles College in Kuala Lumpur, Malaysia, and now runs his own studio, AW Metalsmith.

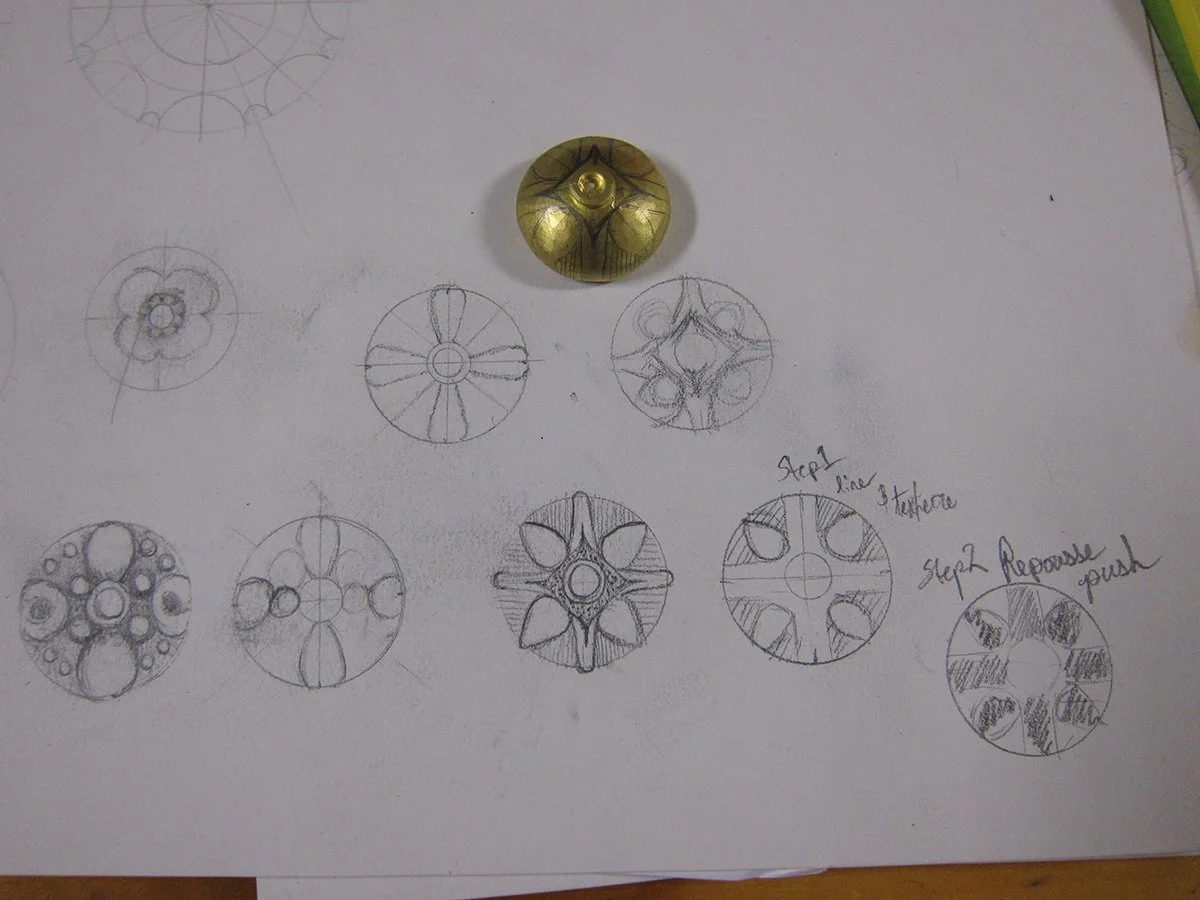

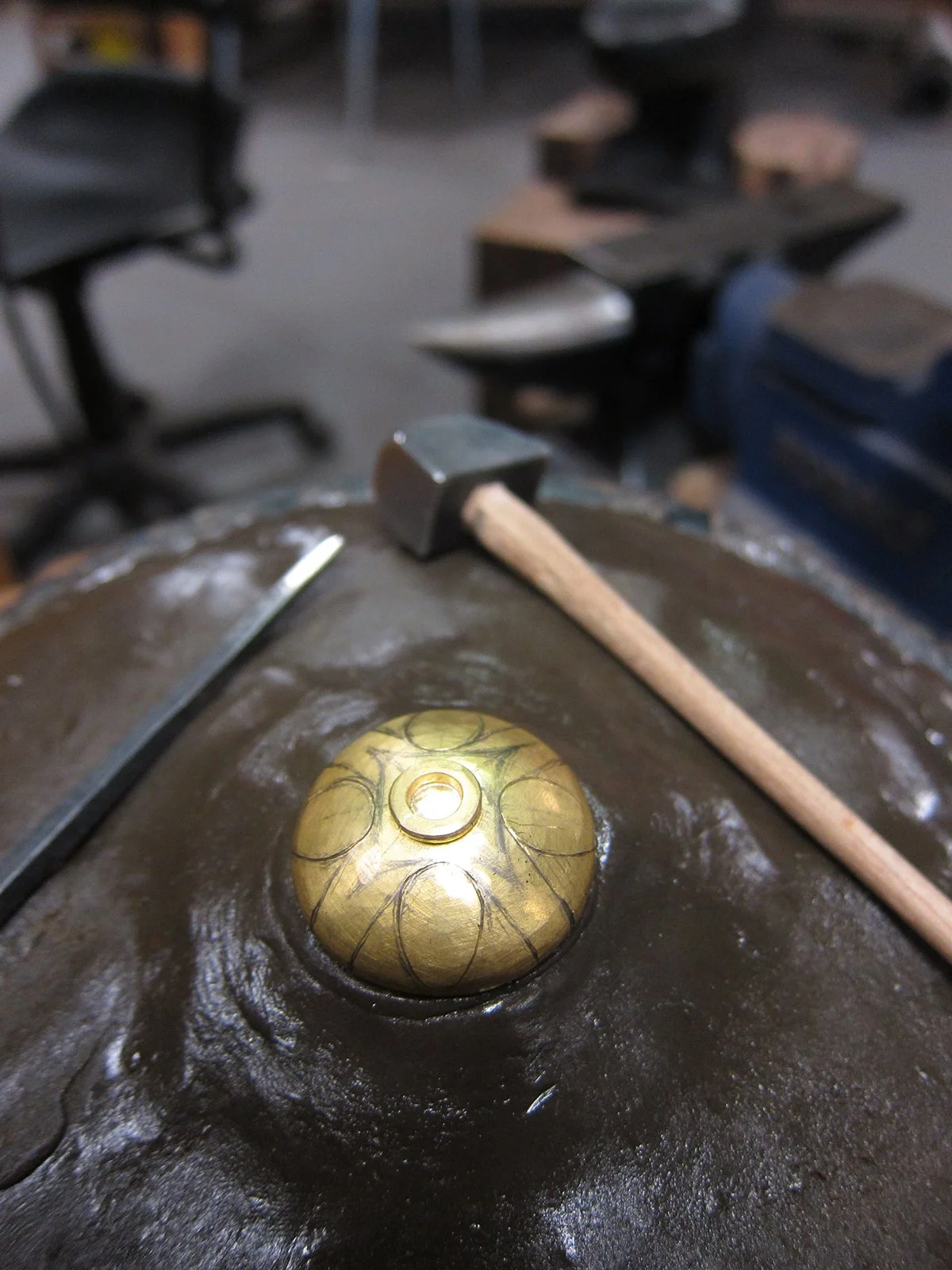

How do you weigh what techniques and materials you will use?

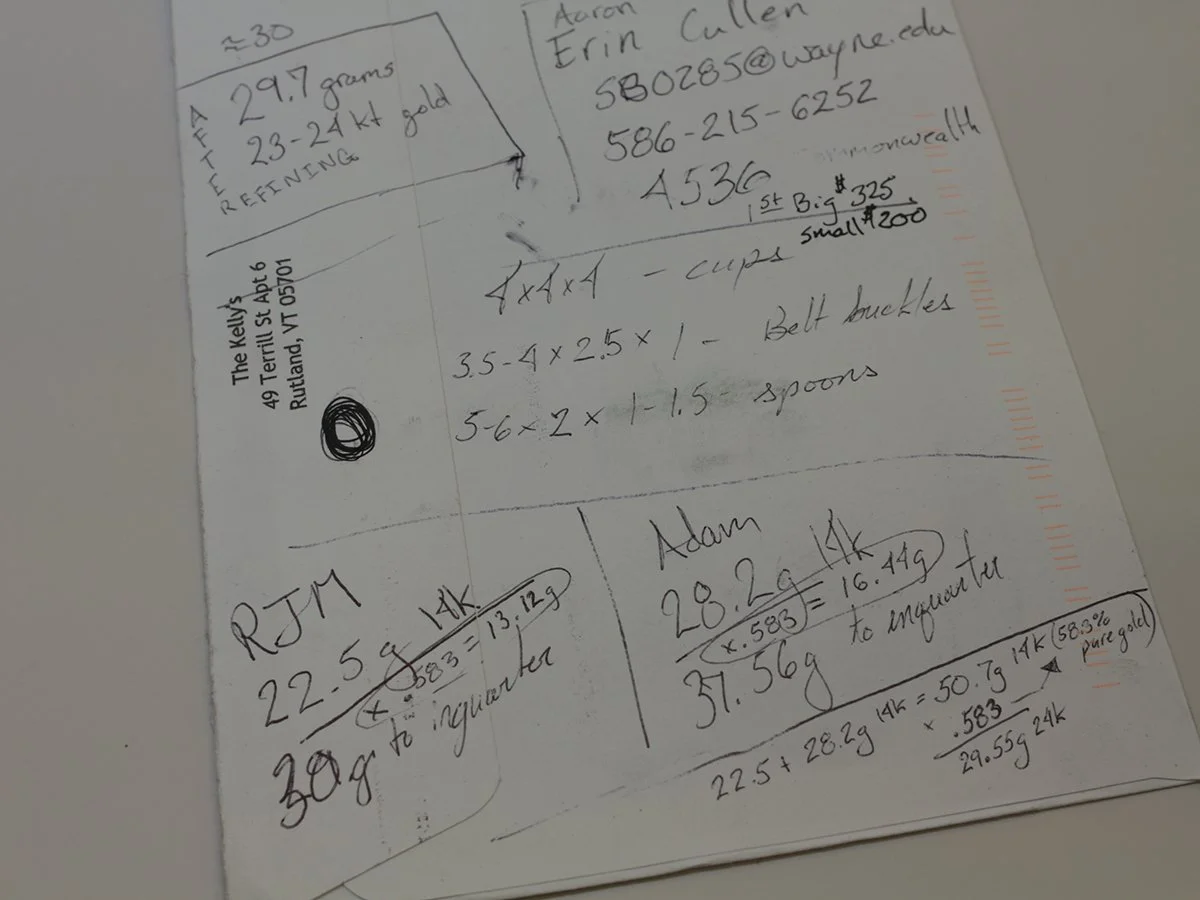

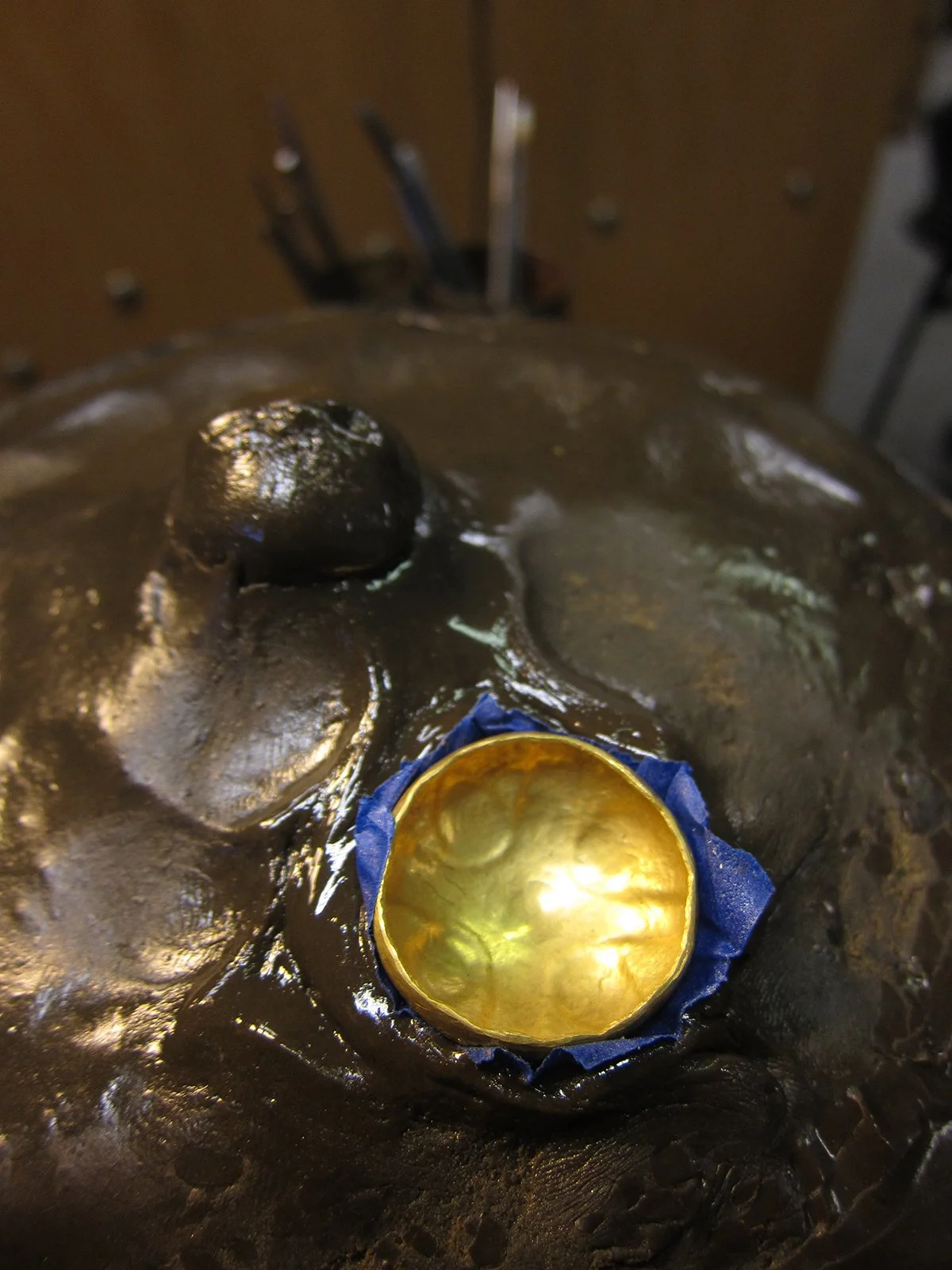

I’ve been given a wide range of materials and have grouped them according to their metal. The first step is to refine the various low karat gold I have been given to use. Some of the gold has already been melted and made into new material, but the resulting alloy is very difficult to work with. Melted and reclaimed 14k & 10k gold tends to result in a brassy colored gold instead of a bright buttery yellow of higher karat gold it’s also brittle and cracks, making it difficult to work with.

Precious metal, especially gold is such a great reusable material but when it’s alloyed down to a lower karat it becomes more difficult for a studio jeweler to reuse. I will refine the lower mixed karats back to an almost pure 24k gold, through a chemical refining process. I dislike the use of chemicals but unfortunately this is one of the only options I have to refine the gold on my own. The result will be 22.5g of 14k/10k, to 13g of 23k. As I engage the other materials I will add to this question.

How have you been influenced by the project?

Quantity, the shear volume of donated jewelry that people are willing to part with is shocking. I have been involved with three RJM events and seeing the amount of donated material is powerful. As a maker of one of a kind jewelry/objects time and value are poured into the pieces. But when you look at a mound of random unwanted jewelry it makes one think about the value; monetary, sentimental, or the fashionability of jewelry.

How do you anticipate future uses for the materials that you are using?

Yes, by raising the karat of the gold I hope to encourage future use of the material especially at a bench level, which will not require the assistance of a refinery, or additional fresh gold added.

Will a jeweler in the future be able to reuse your piece by disassembling or melting down the metal?

Yes.

Adam’s Refining Process

Adam Whitney on Refining

Refining gold in a small studio or sending it off to a refinery is an important conversation that I’ve been thinking about. When I traveled in India I was amazed at the abundance of gold jewelry and how it’s worn by everyone. When I meet with goldsmiths, and attempted conversation, they informed me that the majority of gold jewelry was high karat 22-24. The high karat gold has a beautiful color but its also easy to work with for jewelers; ductile for stone setting & stamping, clean so less chemicals are used in keeping it clean (flux) and cleaning it (pickle), and most importantly it is extremely reusable.

When I got the various gold pieces for RJM the first thing I thought was, what can I do with such a highly praised material that is almost unworkable. When remelting the various gold karats the resulting material is hard/brittle to work with as raw material so the best I could do with it would be to cast it, but from my experience I would still end up with a brassy color and potential pitting and cracking. This is evident in the already attempted gold sheet that was included, I assume this was melted down in a previous RJM and rolled into sheet but unused because of its numerous cracks, splitting, and poor coloration.

Having previous experience, and disappointment, with melting mixed karats of gold and having seen high karat gold jewelry being remelted & reused so easily in India I concluded that I would attempt to refine the RJM gold. Deciding which process I would use to refine the gold took some research and fortunately I was utilizing the studio at Penland School of Crafts and I was capable of safely venting any off gasses and disposing of the acid via a hazardous waste management program. I would not recommend this refining process for all small studio jewelers, especially if you do not have proper ventilation or know how to properly dispose of hazardous chemicals.

In doing my research I came across different gold refining systems/techniques which claim to be less hazardous but I have no experience with these systems.

Unfortunately I don’t think refining gold, they way I did it, is advisable in a small studio. Even if a studio is capable of safely & environmentally working with and disposing of the chemicals used I don’t think it’s time efficient. I enjoyed figuring out and refining the gold but I can’t justify spending the time required to refine the gold for a specific project. If a client came to me wanting to refine and reuse 1oz of mixed karat gold without purchasing new gold I would consider it, but I wouldn’t want to commit to this process for multiple clients. I want to spend my time as a Designer/Maker rather than refining metal. If I had a large quantity of mixed karat gold to be refined I would rather send it to a refinery because it would exceed most small studios abilities; larger containers, more acid, bigger fume hood, more safety and environmental risk.

What is frustrating to me is that gold in a purer form 20-24k is extremely reusable, it can be melted down quickly and retains a high level of workability. But when gold is alloyed with various other metals and the karat is lowered to 10-18k, it becomes difficult for small studio jewelers to reuse. In India the gold karat is kept high and the local jeweler is capable of reusing the material without need of refining.

I don’t think the answer is in refining, but in changing the quality of material we use.