Amy Weiks and Gabriel Craig are a Detroit-based artist team. While working predominantly in metal, their holistic practice includes writing, craft advocacy, and educational activities. Their artistic work has been exhibited at venues including the Renwick Gallery of the Smithsonian American Art Museum in Washington, D.C., the Museum of Contemporary Craft in Portland, OR, the Contemporary Arts Museum in Houston, TX, the Mint Museum in Charlotte, NC, and the Metal Museum in Memphis, TN. Their critical writing has appeared in craft publications including Metalsmith, American Craft, and Surface Design Journal. They have lectured widely throughout the country and held numerous residencies including at the Houston Center for Contemporary Craft in 2009-10, the California College of Arts in 2013, Warren Wilson College in 2015, and Haystack Mountain School of Crafts in 2019. In 2012, Weiks and Craig founded Smith Shop—a nationally acclaimed metalworking studio in Detroit that produces functional and ornamental metalwork ranging from jewelry to architectural ironwork. Smith Shop has been recognized for excellence through numerous awards and by publications including Saveur, Food & Wine, Metropolis, Dwell, and American Craft. Craig received his BFA from Western Michigan University and his MFA from Virginia Commonwealth University. Weiks earned her BFA from Western Michigan University and her MFA from Cranbrook Academy of Art. They reside in Detroit with their daughter Cecilia and their canine companion Wilmo.

How have you been influenced by the project?

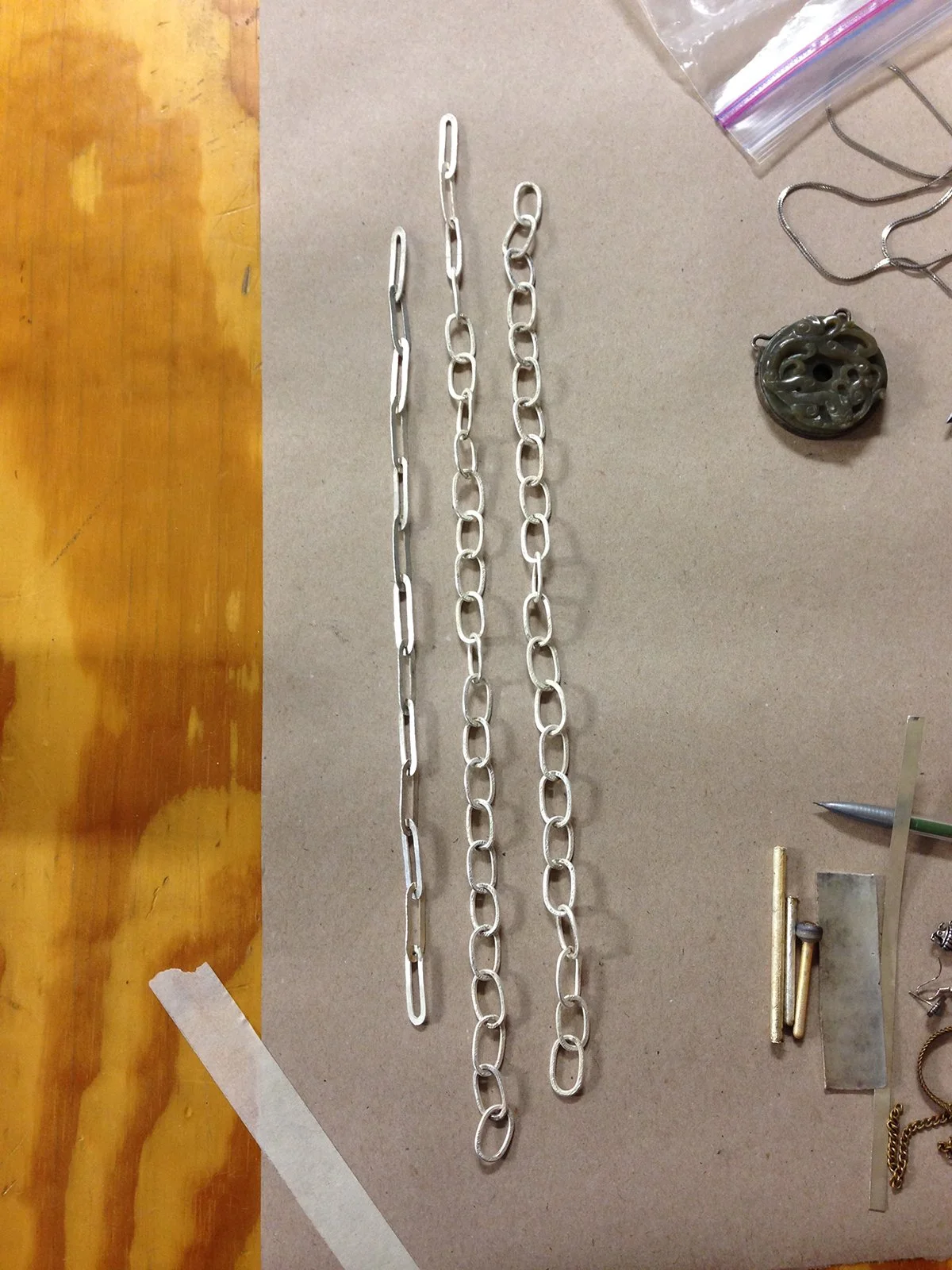

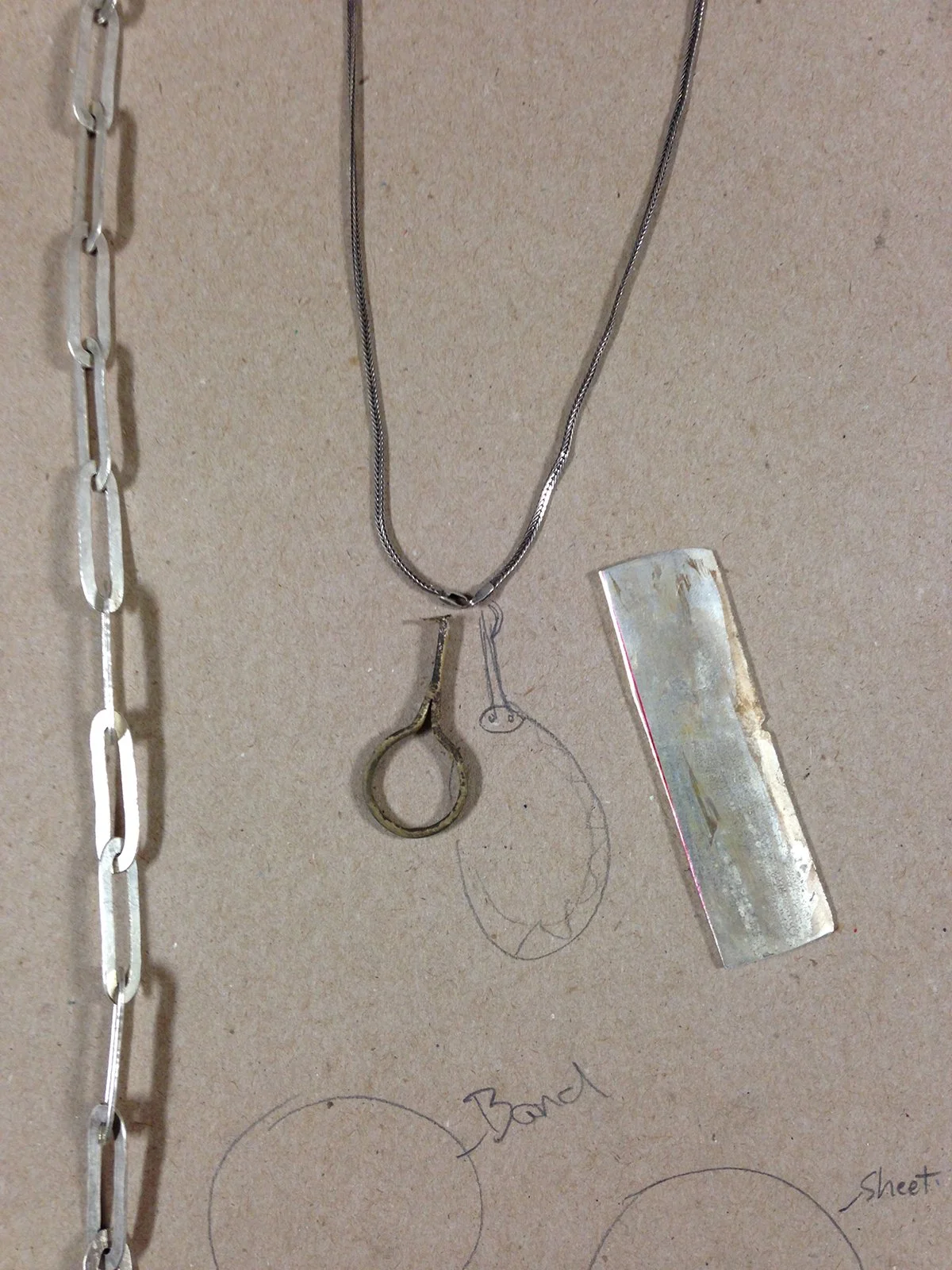

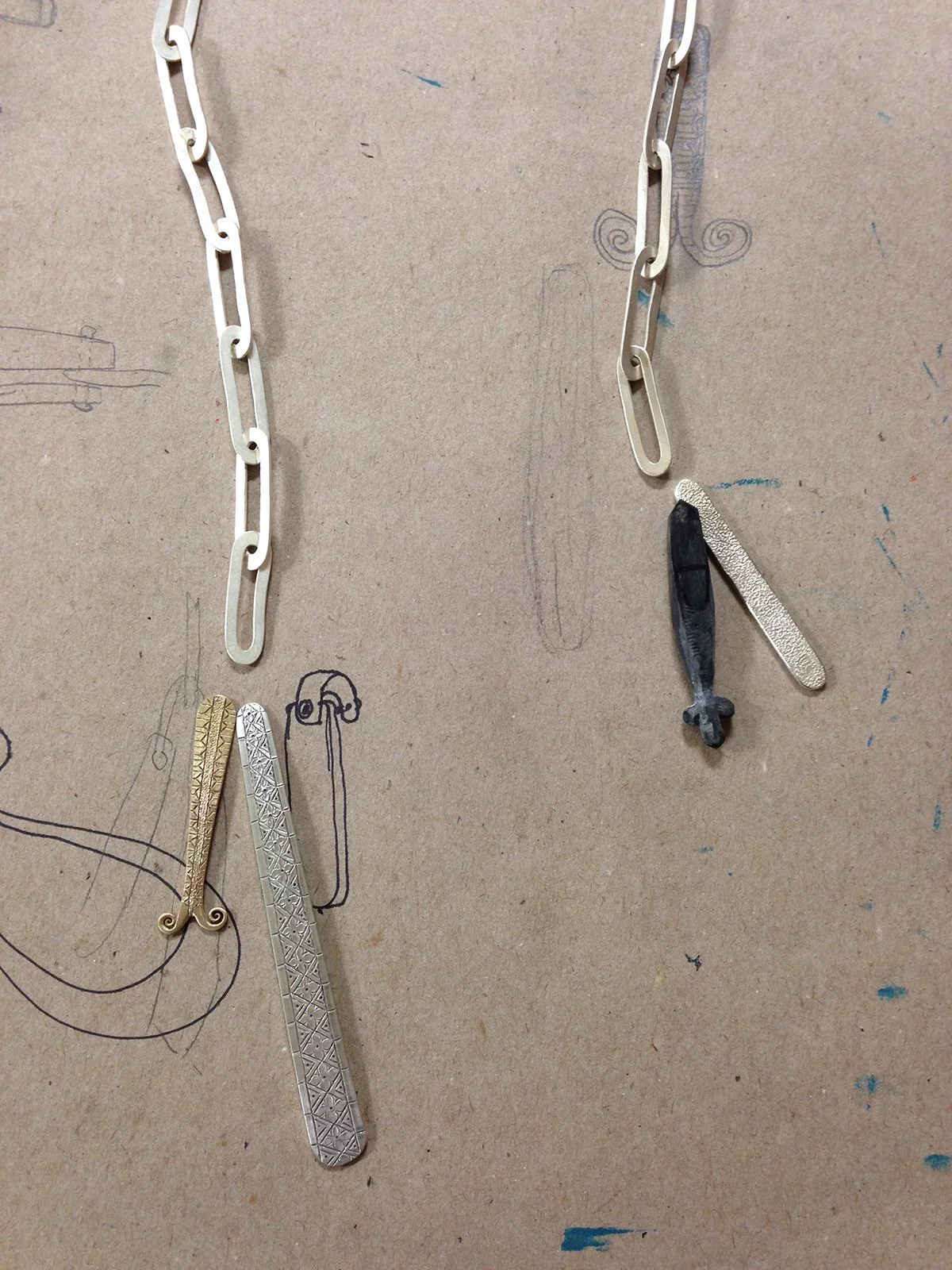

Since Gabriel first participated in the project, and even before when he was studying with Susie at Virginia Commonwealth University, ethical material sourcing has always played a large role in our approach to making jewelry. Immediately after Gabriel’s participation in RJM we embarked on a yearlong collaborative body of work with used upcycled watch fobs, coins, and recycled silver, gold, and ethically sourced gemstones in some pieces. Today we only use precious metal that is recycled and transparently sourced. In December 2013, we were commissioned to make 20 sterling silver belt buckles, each belt buckle was made from 3 ounces of in-house recycled sterling jewelry and flatware.

We continue to strive towards using exclusively recycled non precious metal in our copper, brass, bronze, and steel work by amassing stockpiles of those materials to work from, but that is not always practical. We look forward to recycling and sourcing our own material until such time as those materials have a transparent and recycled supply stream. It can’t be overstated how much RJM acted as a proving ground and catalyst for the complete overhaul of our professional sourcing activities.

How do you weigh what techniques and materials you will use?

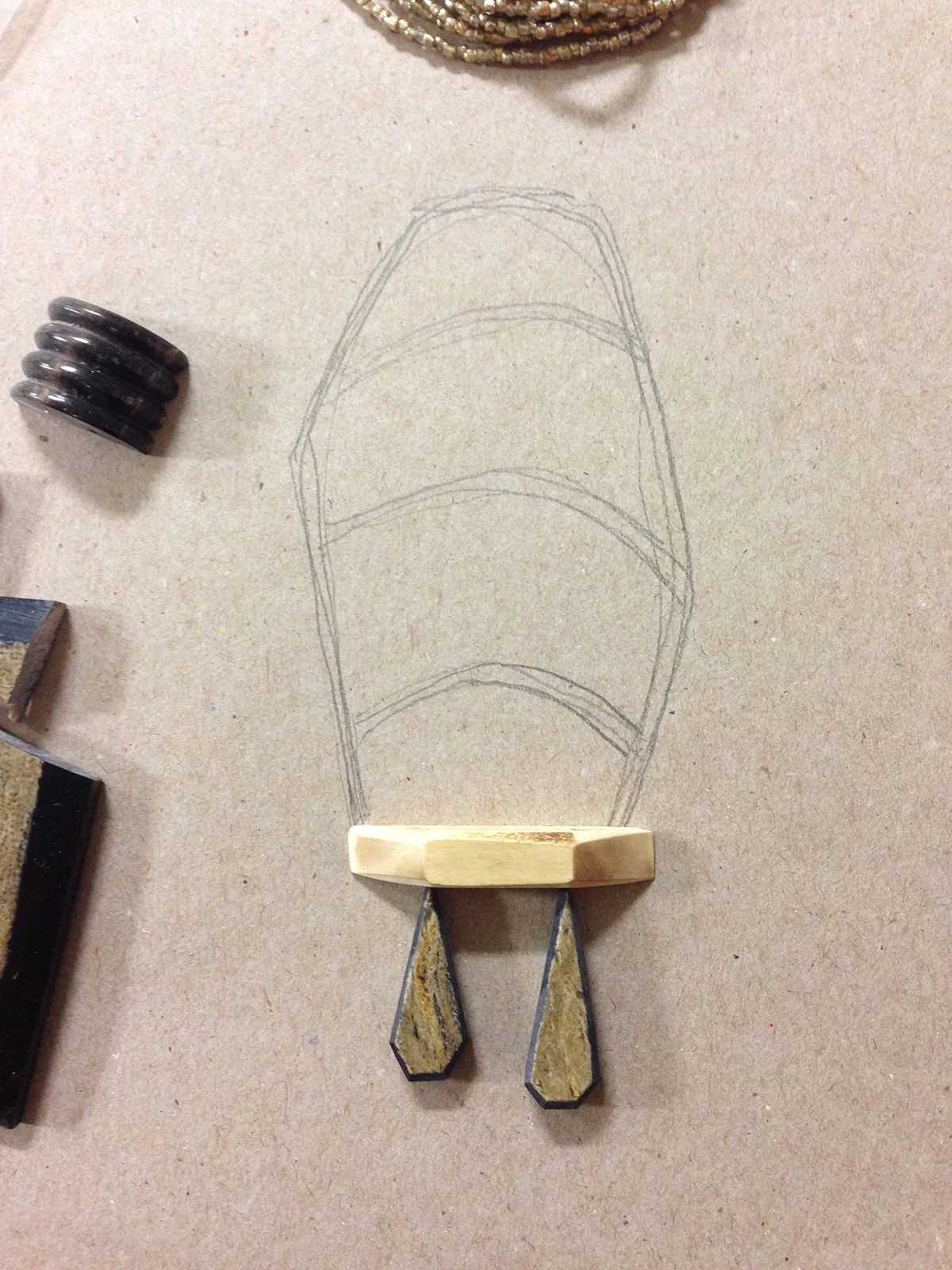

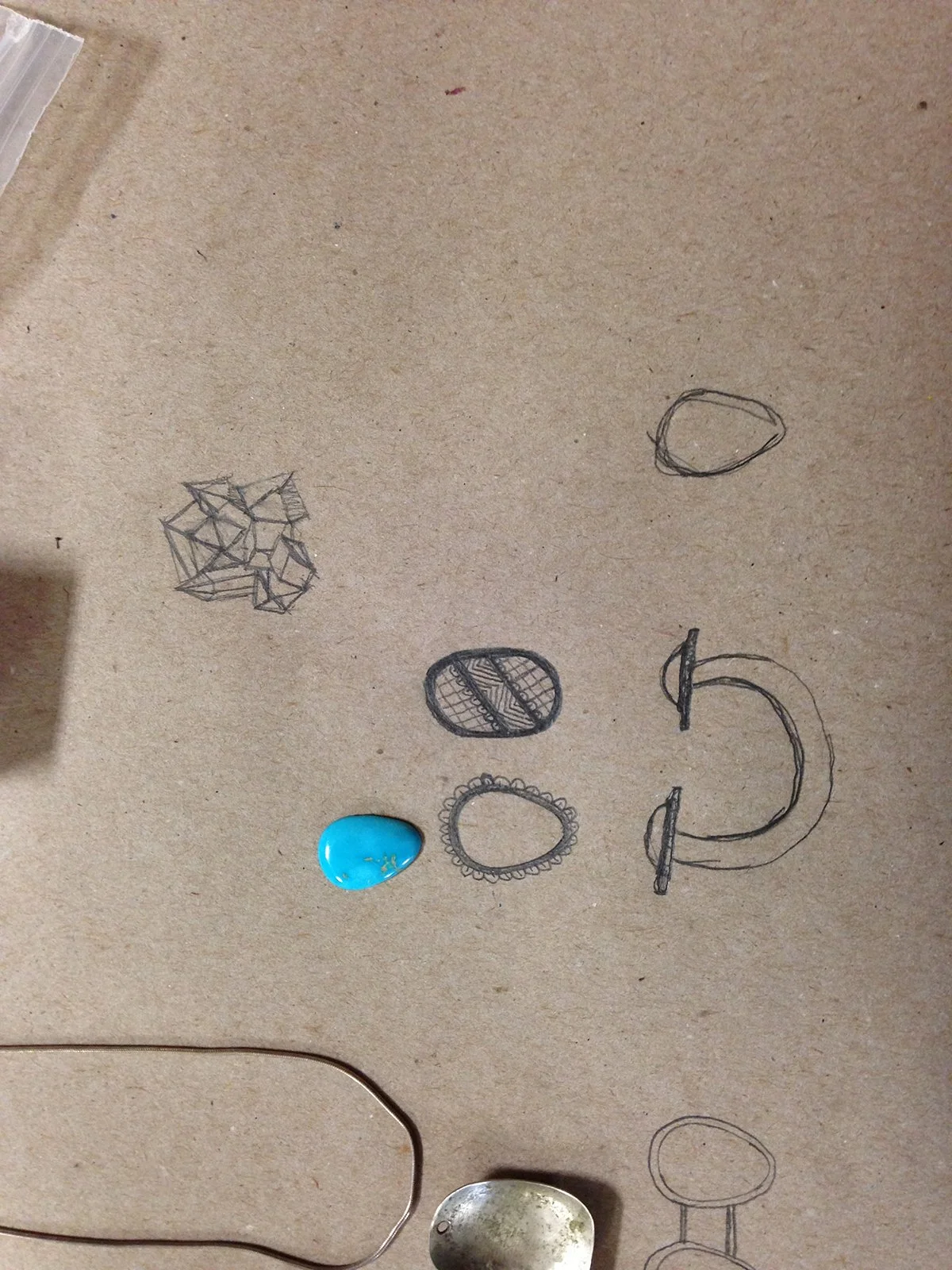

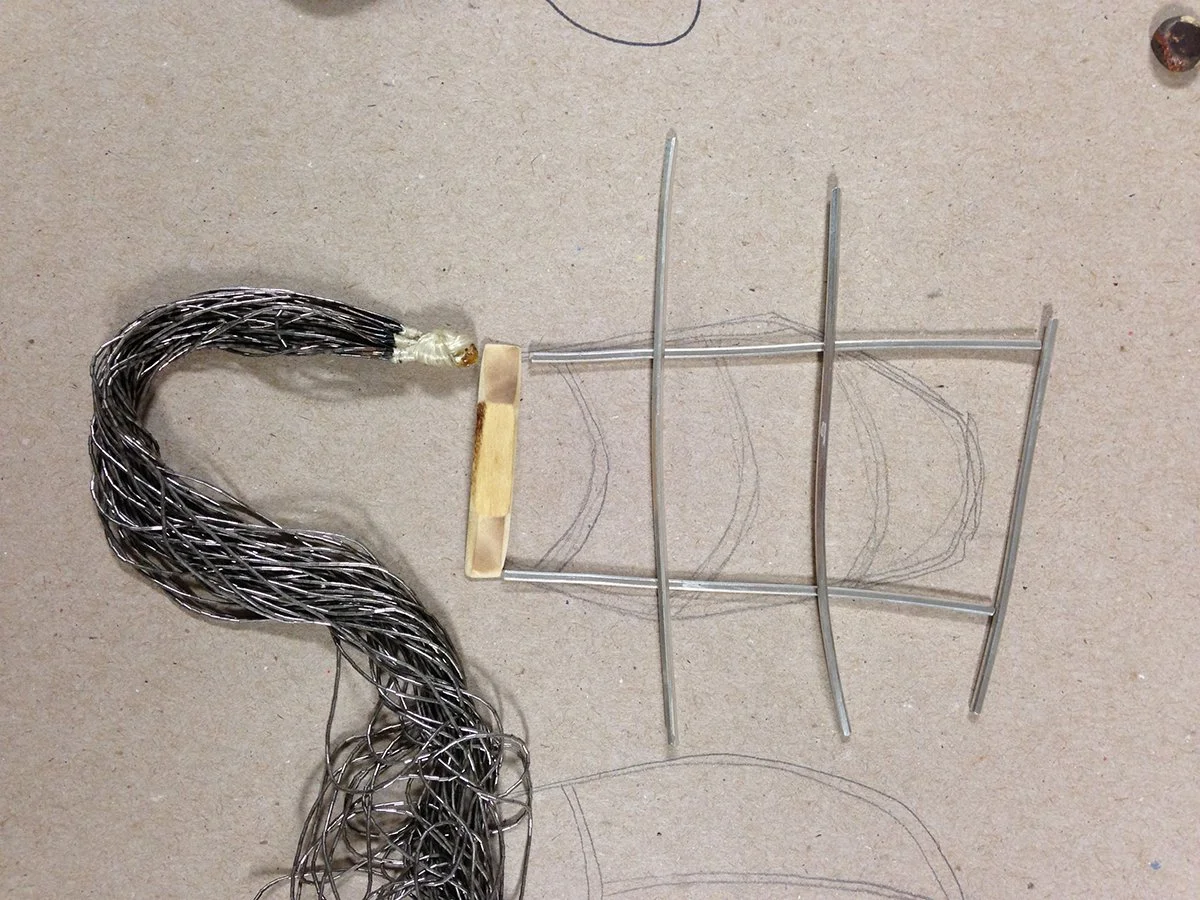

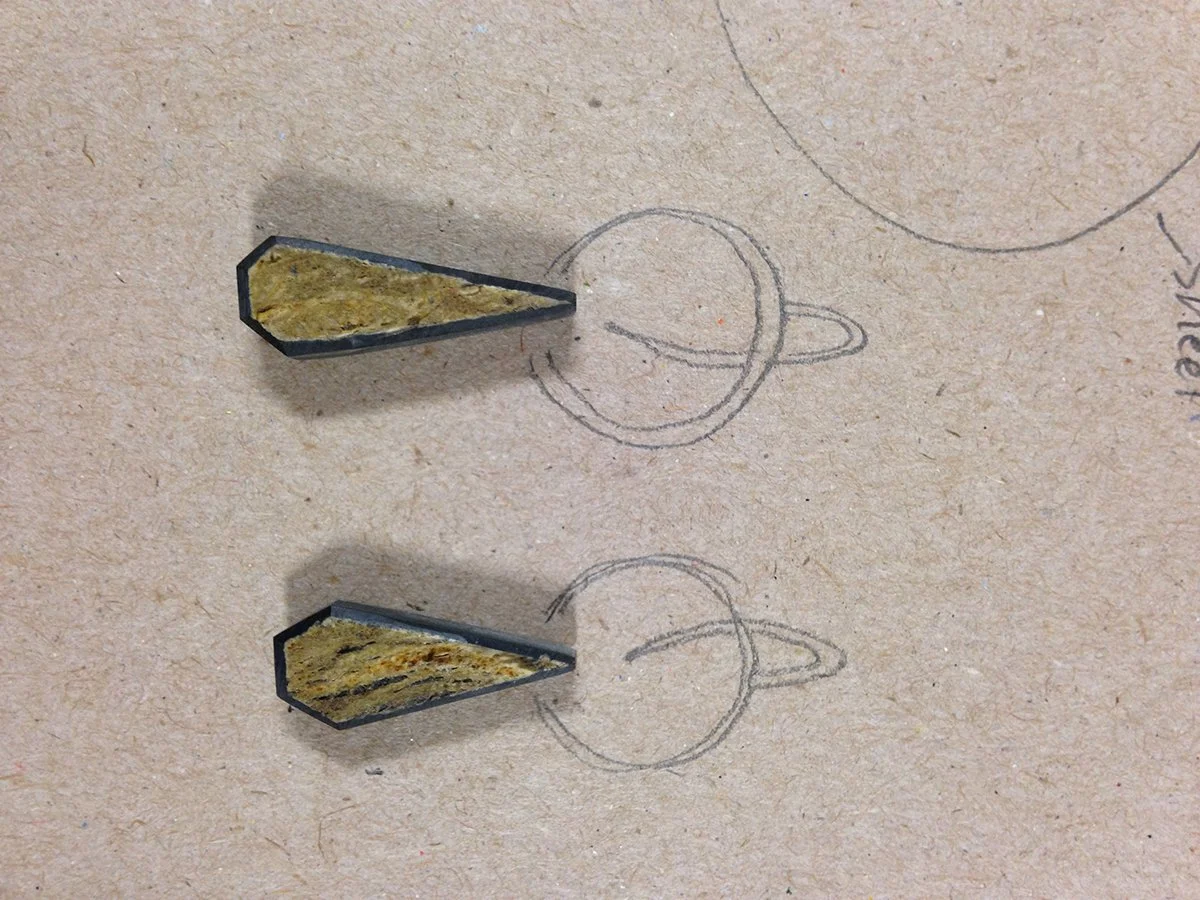

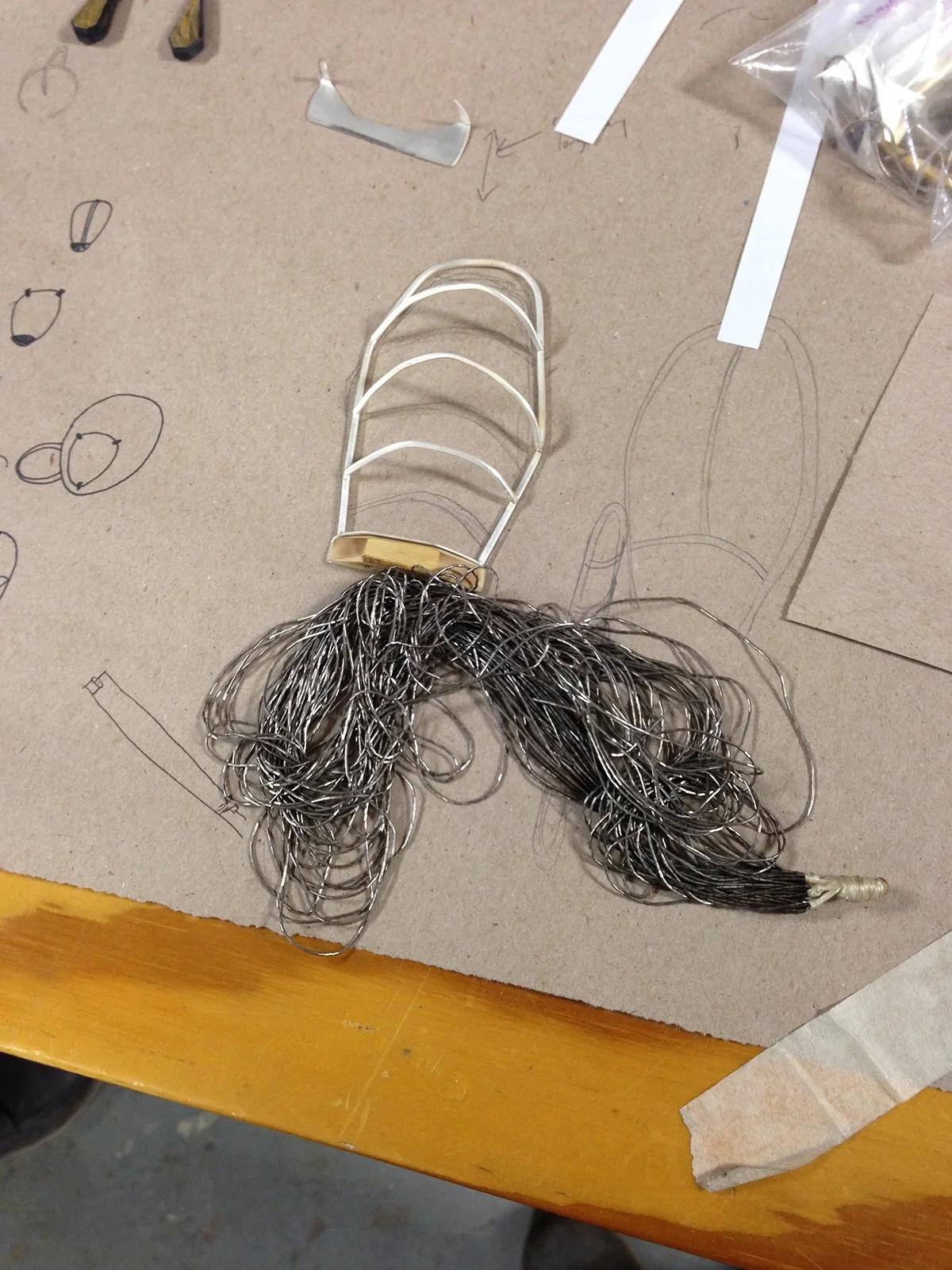

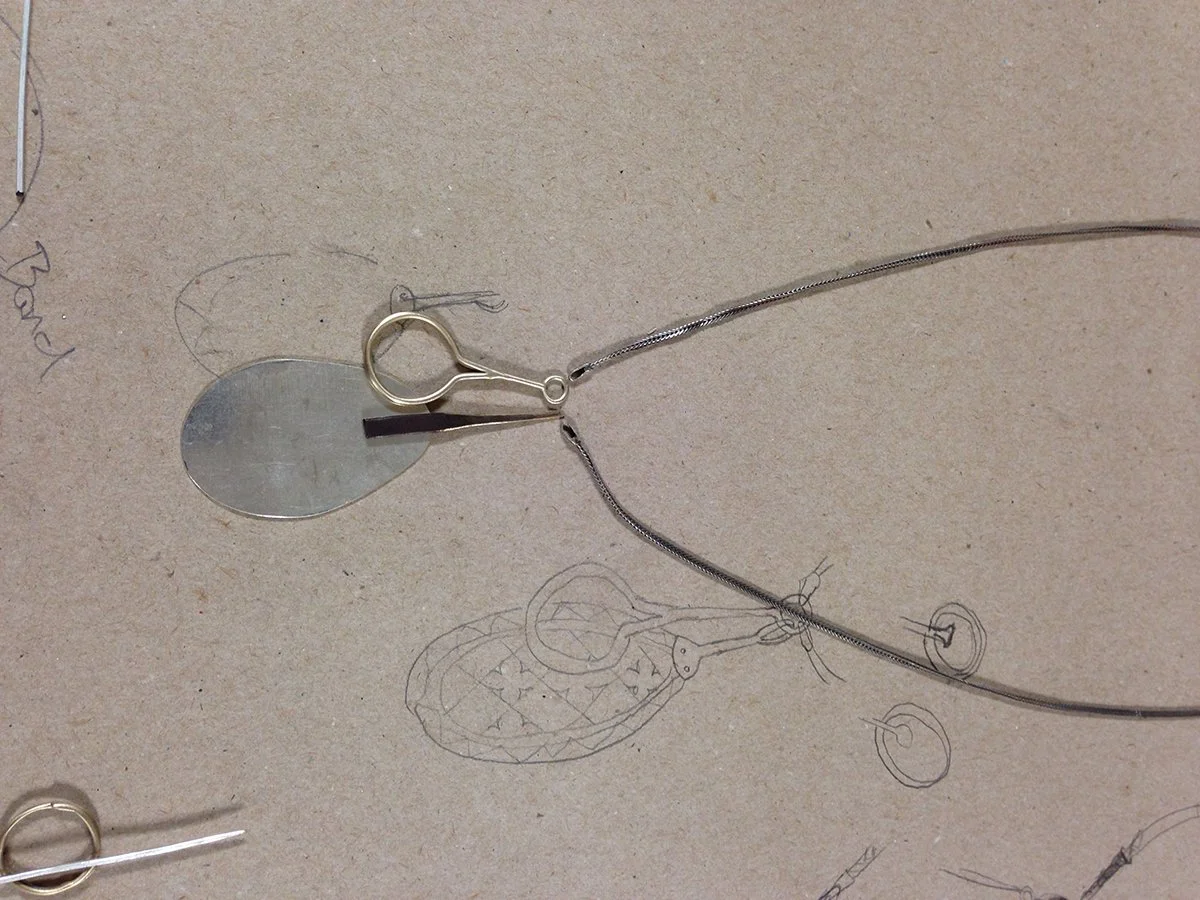

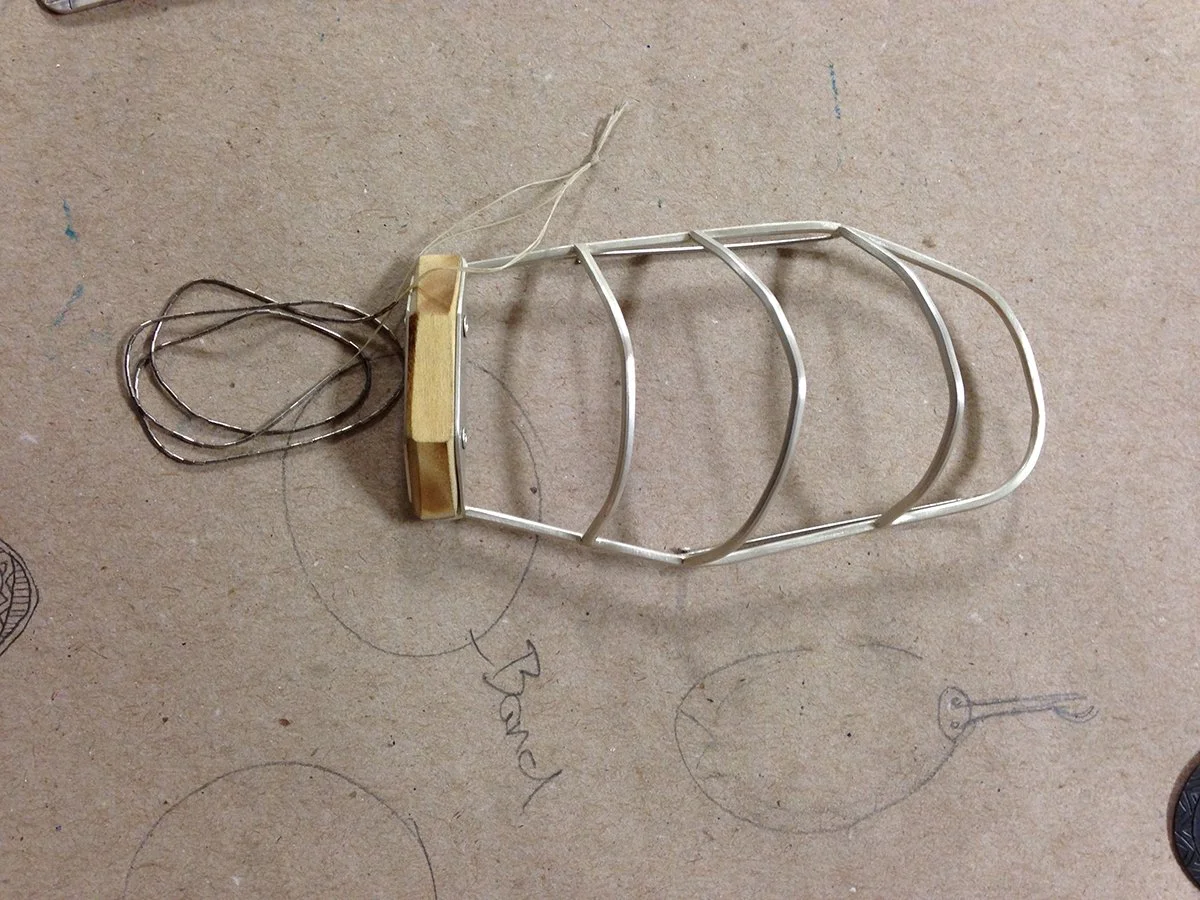

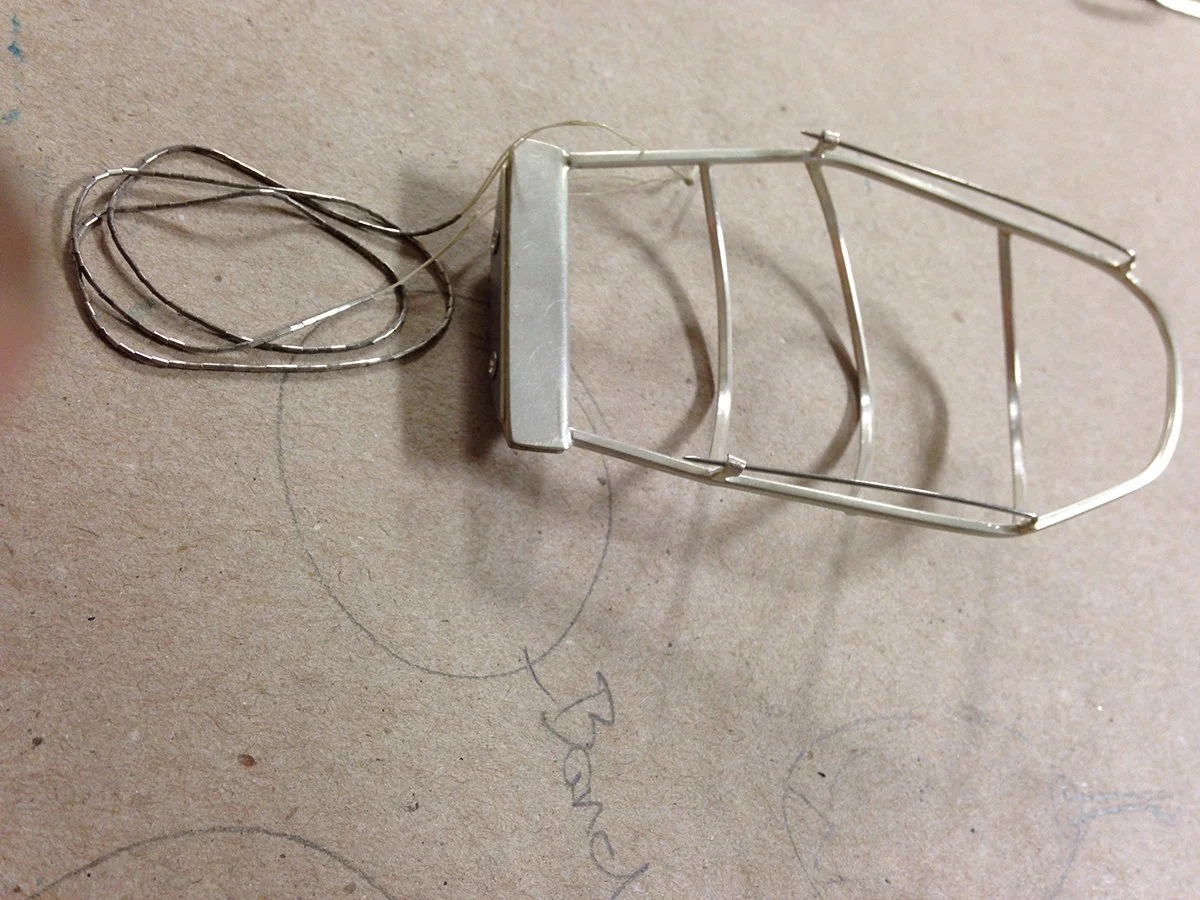

I don’t think this is something we consider often. We use a wide variety of traditional metalsmithing techniques. If something is toxic to us or the environment we generally stay away from it. Our artistic interest often correspond the inherent properties of the metal we are using. Therefore, we favor techniques like sawing, forming, forging, and soldering which manipulate the material, rather than techniques like etching, resin inlay, and niello which create waste chemicals or render the material difficult to recycle. In our work we almost exclusively use metal, or other ethically sourced materials, despite the critical popularity of Contemporary (European Influenced) Art Jewelry, which is material agnostic. We are ethically minded metalsmiths. Every new project we make a conscious choice to work in metal and to have that metal be ethically sourced to the best our ability and ingenuity.

How are creative license, personal safety, environment, and social responsibility factored in to your choices?

But choosing to source recycled material, and often recycling it ourselves, we know we are losing certain desirable working properties. For example, recycling sterling silver to make an 18 gauge sheet suitable for raising hollowware is not really an option because it will be too prone to cracking. In that situation we would use sterling bought from an independently certified recycled metal content refiner such as Hoover & Strong or we would use upcycled copper from the building trade. And while forming large sterling sheets presents some difficulties pouring a ¼” x 6” sterling ingot from scrap to make a belt buckle is no problem. Often we see imperfections caused by recycling as intrinsic to our process. We just have to be careful that they do not affect the quality of functionality of the finished product. Often it is our goal to transform a raw or recycled material to the extent that it is no longer recognizable as the original material.

How do you anticipate future uses for the materials that you are using?

To be honest, this is something we don’t think about very often. By and large though, by working with traditional techniques, in traditional modes our work would be very easy to reverse engineer for anyone familiar with jewelry fabrication looking to take apart or recycle our work. And even more generally that is often the difference between small manufacturing and large, the emphasis on quality construction and materials in contrast to cold efficiency and cost per unit.

Will a jeweler in the future be able to reuse your piece by disassembling or melting down the metal?

Yes